3D Laser Scanning is an emerging technology which is revolutionising digital data capture for 3D usage. Across all industries, 3-dimensional environments have become the standard for design, presentation and engineering. Laser scanning allows real world environments, identified equipment and facilities which all can be captured in 3D exactly as they are. The technology used in this sector has changed dramatically to this present time. From theodolites, prisms and tape measures to advanced total stations and super-fast 3D laser scanners. Always looking to the forefront of technology, digital surveyors were the earliest adopters of 3D laser Scanning and have become highly proficient in using this equipment. Laser scanning creates an exact 3D replica of the item that can be scanned and made up of millions of points of data that can also be termed as point cloud in the survey industry. This point cloud data can be manipulated to obtain accurate dimensions or it can be converted to solid as-built PDMS models allowing designers to virtually test for clash point detections and plan their designs accordingly. In a while, the process data will be gathered and processed by software that produced 3D deliverables. Oil and gas industry is the pioneer among other sector to embrace 3D laser Scanning which will help in reducing a mobilizations cost, safe time, energy and etc.

Example of Product / Deliverables:

- Survey Report

- Red Line Mark-up (RLM)

- AutoCad 3D Models

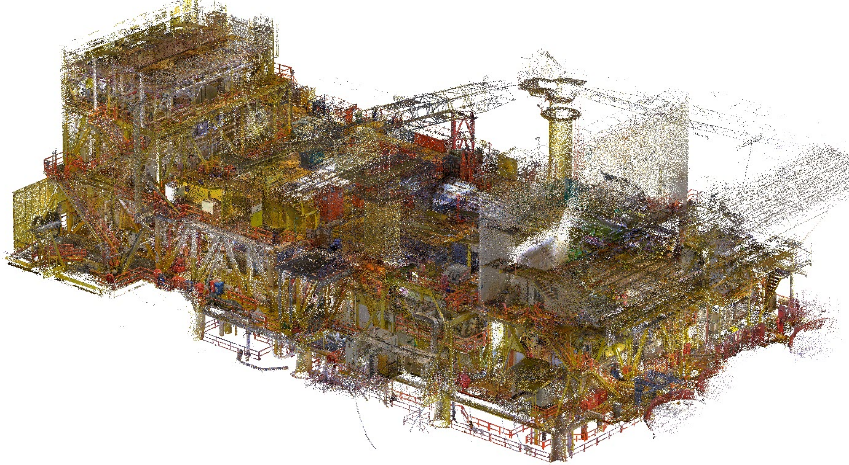

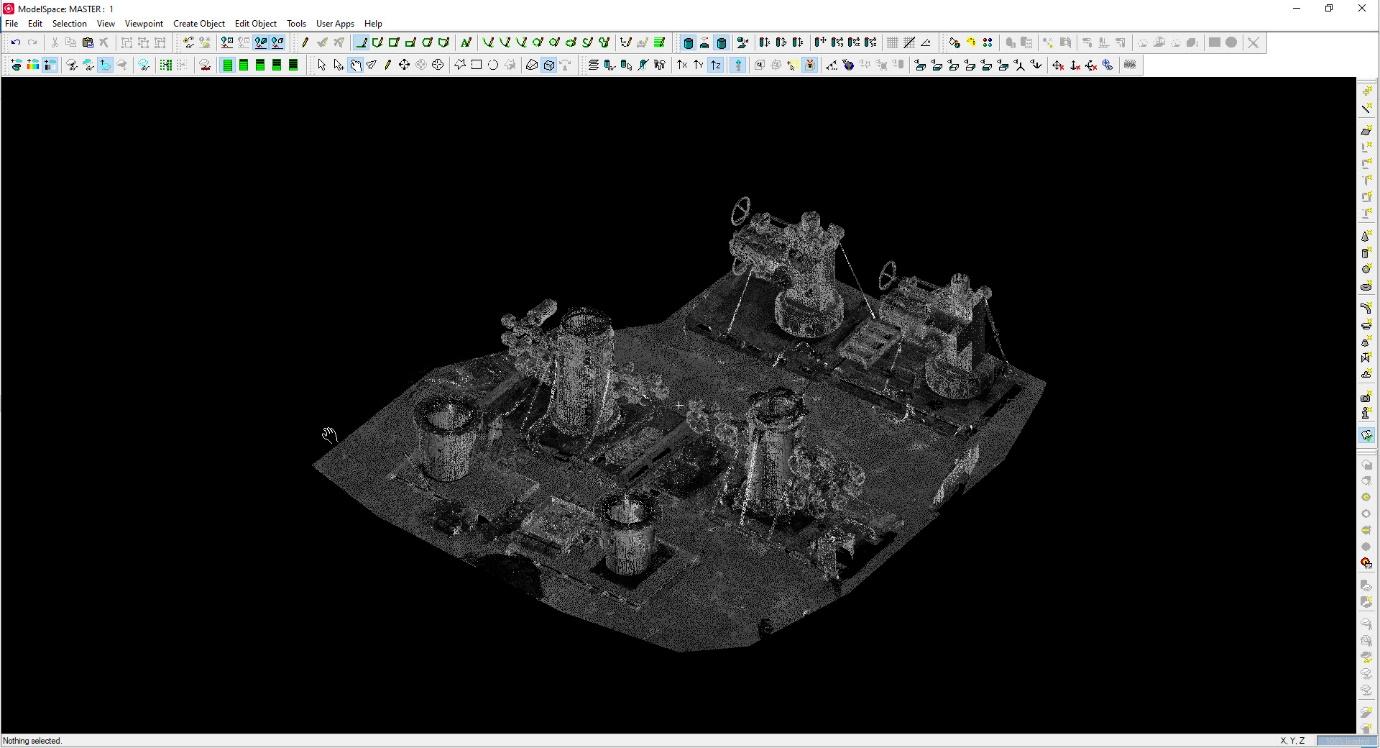

- Laser Scan Generated Point Cloud

- PDMS Model

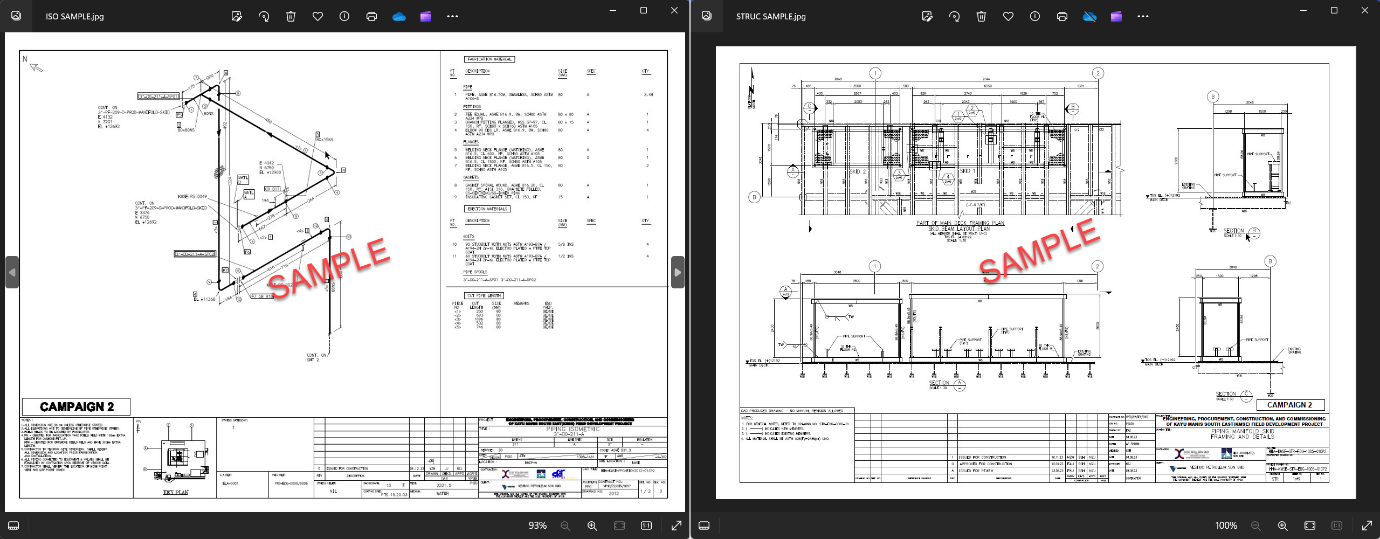

- Piping Isometric Drawings

- Structural Drawings

Dimensional Control Survey (DCS) is a process used in various industries, such as manufacturing, construction, and engineering, to ensure that physical components or structures meet specified dimensional requirements. The primary goal of a dimensional control survey is to verify and validate the accuracy and precision of measurements, ensuring that the final product or construction aligns with design specifications. In order to get a precision measurement a highly accurate measuring instruments and tools are used to collect data on dimensions such as length, width, height, angles, and other relevant parameters. The collected measurements are compared with the intended design specifications, blueprints, or 3D models to identify any deviations. This helps ensure that the final product meets the required tolerances. If discrepancies or deviations are identified, necessary adjustments or corrections are made to align the components or structures with the design requirements. By implementing dimensional control surveys, industries can minimize errors, improve quality, and enhance overall efficiency in the production or construction processes.

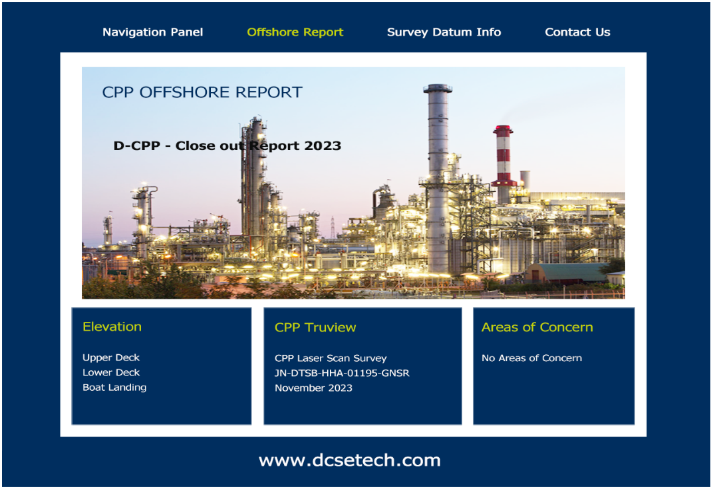

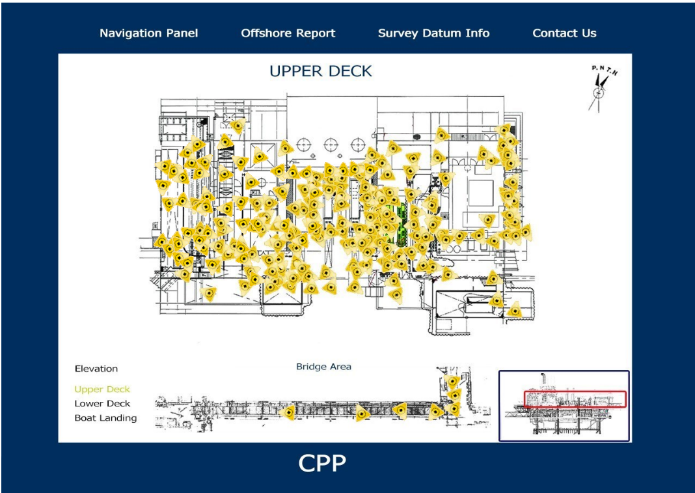

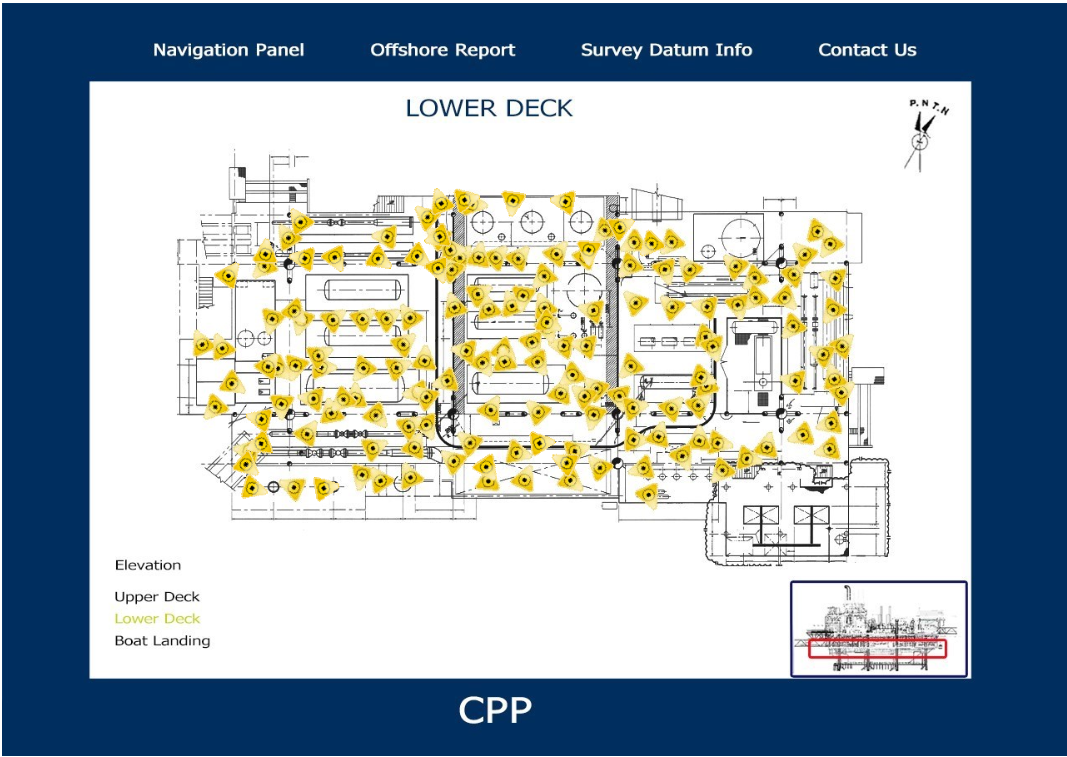

TRUVIEW REPORT

RED LINE MARKUP (RLM)

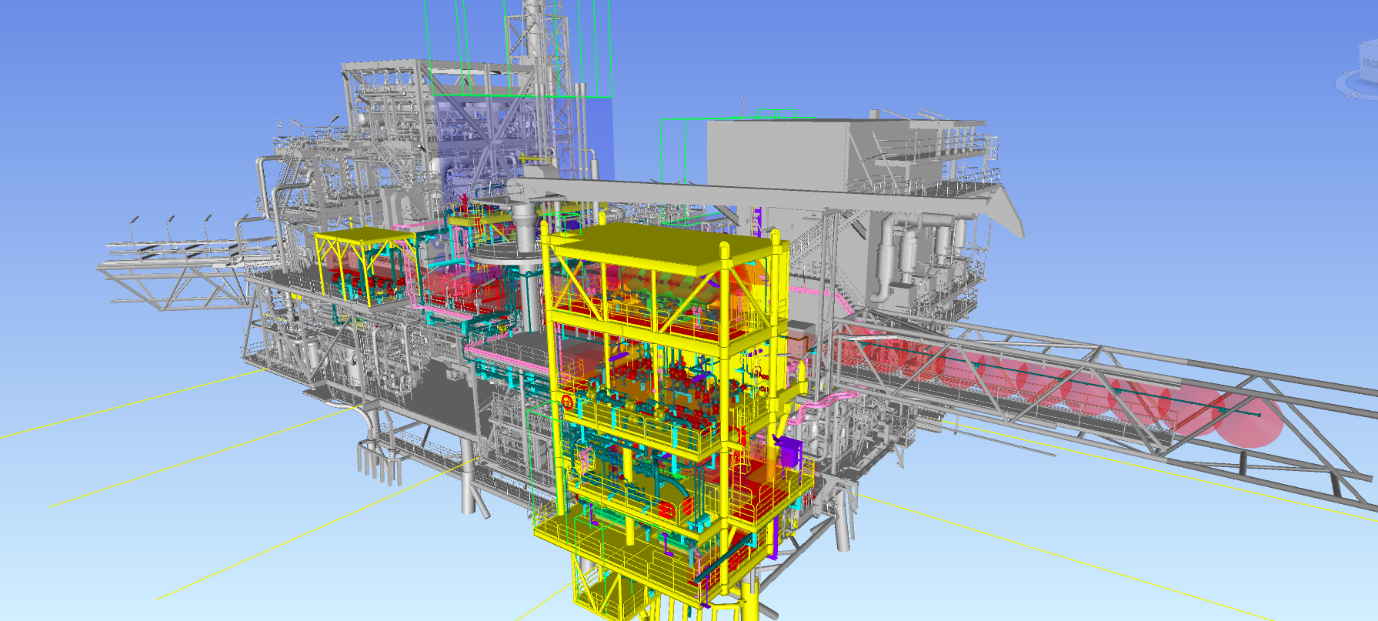

PDMS MODEL

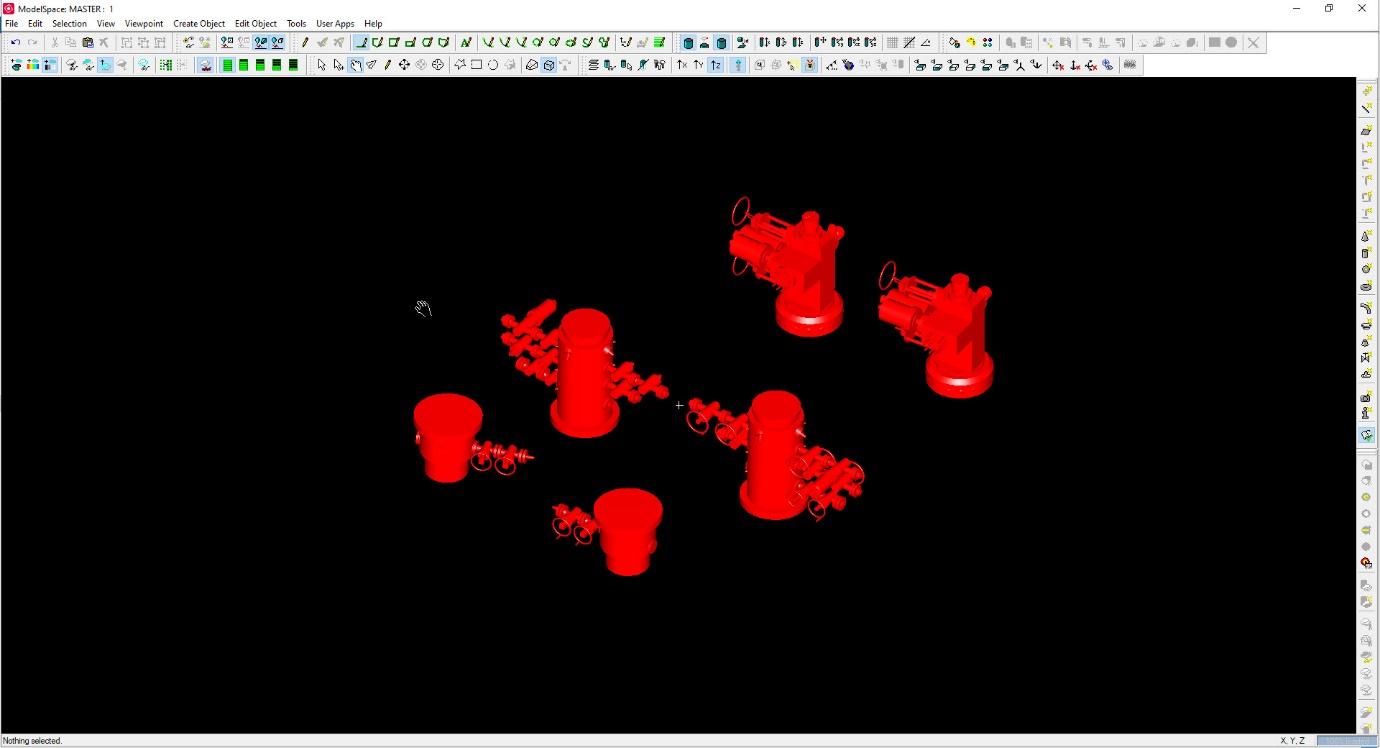

LASER SCAN GENERATE POINT CLOUD

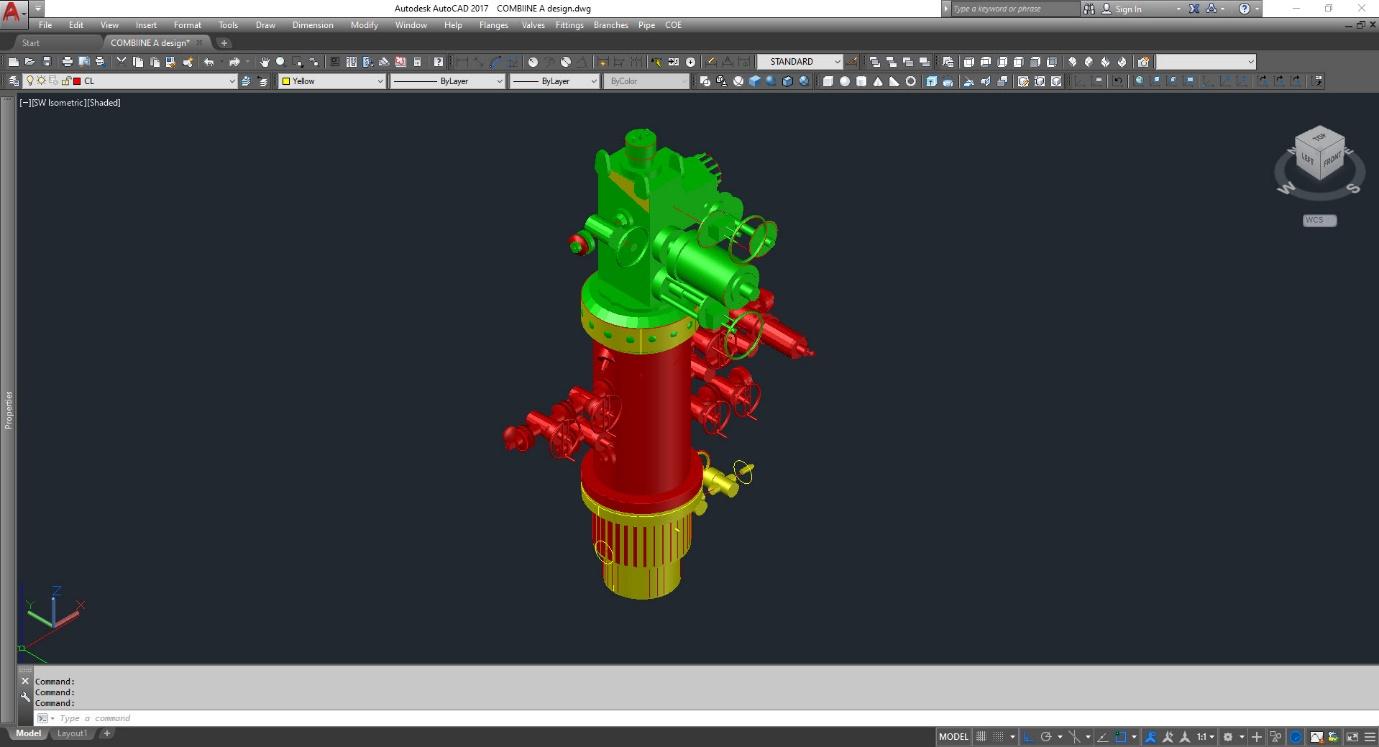

AUTOCAD 3D MODEL

ISOMETRIC DRAWING